Turn Data into Outcomes

At last, a business platform built for Data Teams. Automate work with AI, deliver real business impact.

At last, a business platform built for Data Teams. Automate work with AI, deliver real business impact.

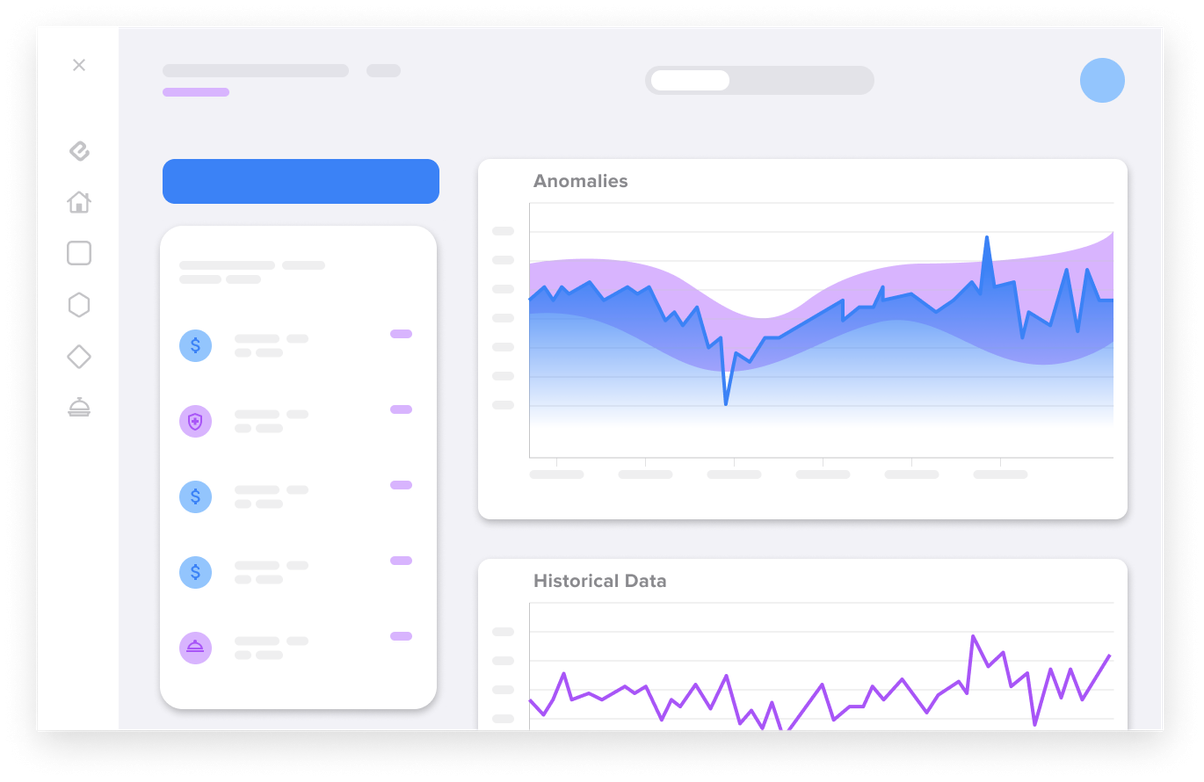

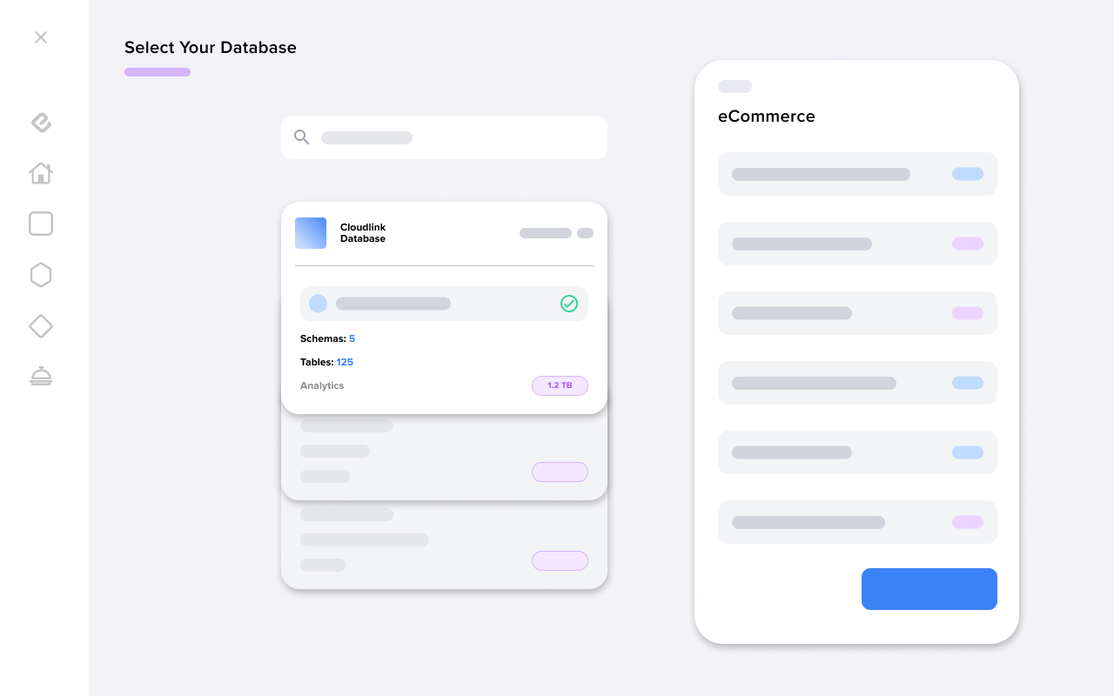

The only workflow automation platform built to operate virtually within modern data clouds. Instantly action your data with turnkey, AI-powered solutions for every industry.

Instantly automate any business process without moving data: No integrations, no APIs, no waiting.

Easily embed advanced data models into your workflows without expertise or complex MLOps infrastructure.

Elementum is trusted by the world's leading companies and brands.

Using Elementum, we’ve decreased our incident resolution time by 60 percent The overall result is that we’ve increased on-time delivery, saved revenue, and increased customer satisfaction.

GCC, Supply Chain Manager

Elementum offers a very powerful value proposition for companies like ours, who are looking to future-proof their operations.

Dyson, Former Chief Executive Officer

Starbucks is finding it effective to centrally manage operational incidents through Elementum. I know who on my team is accountable for managing them; and I know exactly what to tell customers and stakeholders. This is especially helpful as partners are working remotely.

Starbucks, SVP of Global Sourcing & Chief Procurement Officer

Data Leaders need to move beyond insights and start prioritizing automation. Elementum makes it especially easy with data driven workflows.

Albertsons & American Express, Former Chief Data Officer

When it comes to the supply chain, it’s all about how quickly a company can take action. With Elementum's real-time insights, our supply chain will be able to react immediately, instead of waiting weeks or months after a problem arises.

Corning, Former SVP of Global Supply Chain

The number one benefit we’re getting out of Elementum is accountability-- it is very clear who owns the next step in the resolution of customer issues caused by over, short or damaged orders.

Kens, Senior Director of Supply Chain

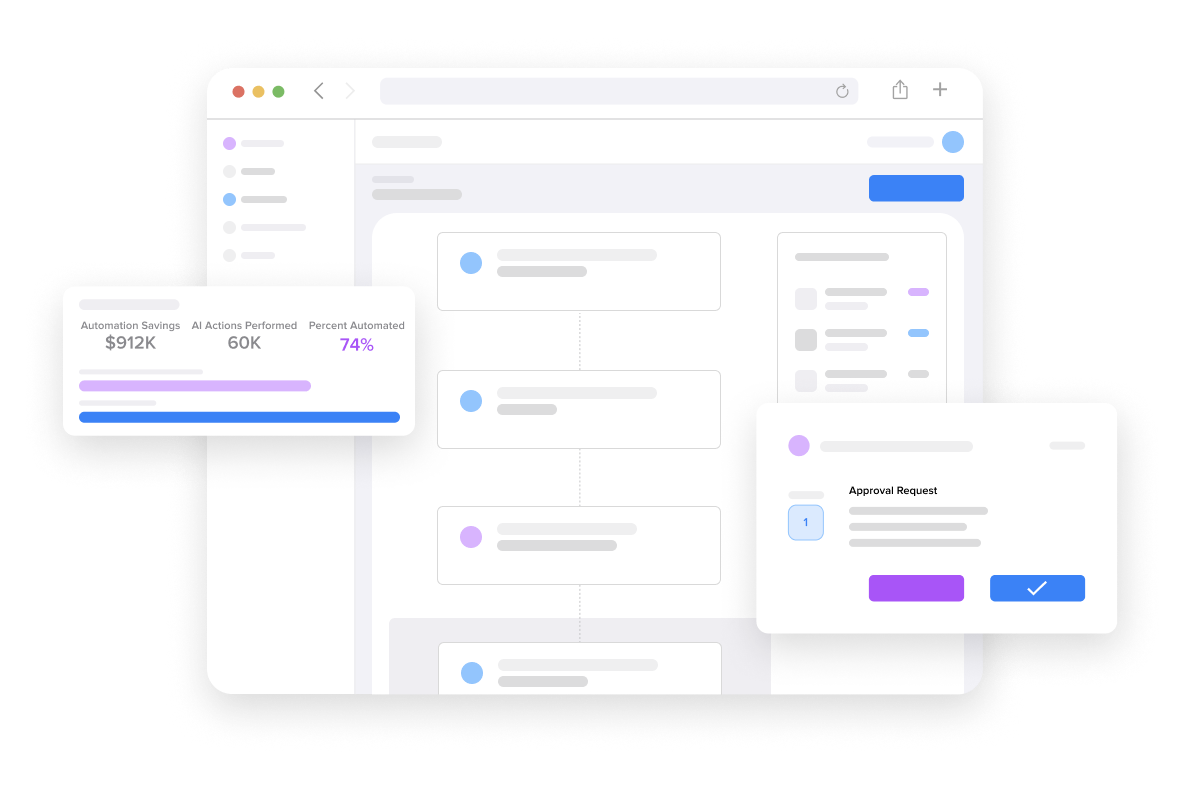

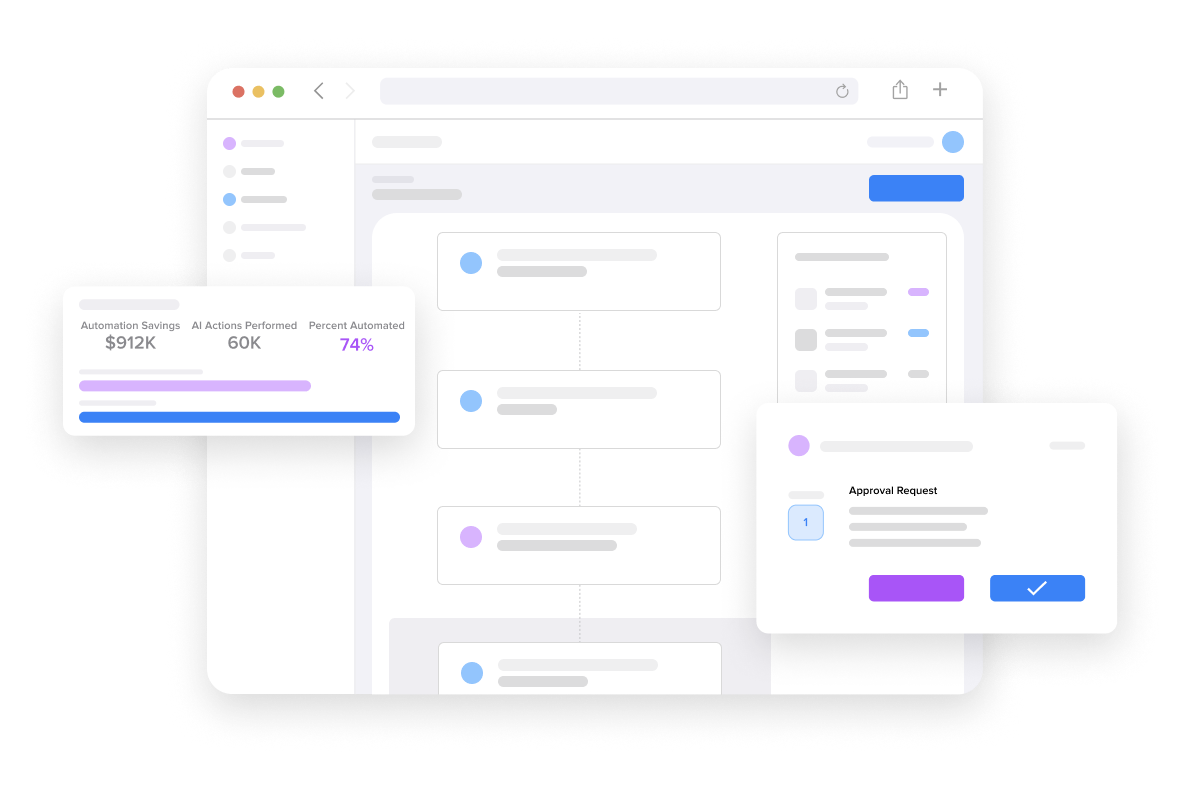

Elementum is the fastest way to automate modern business processes.

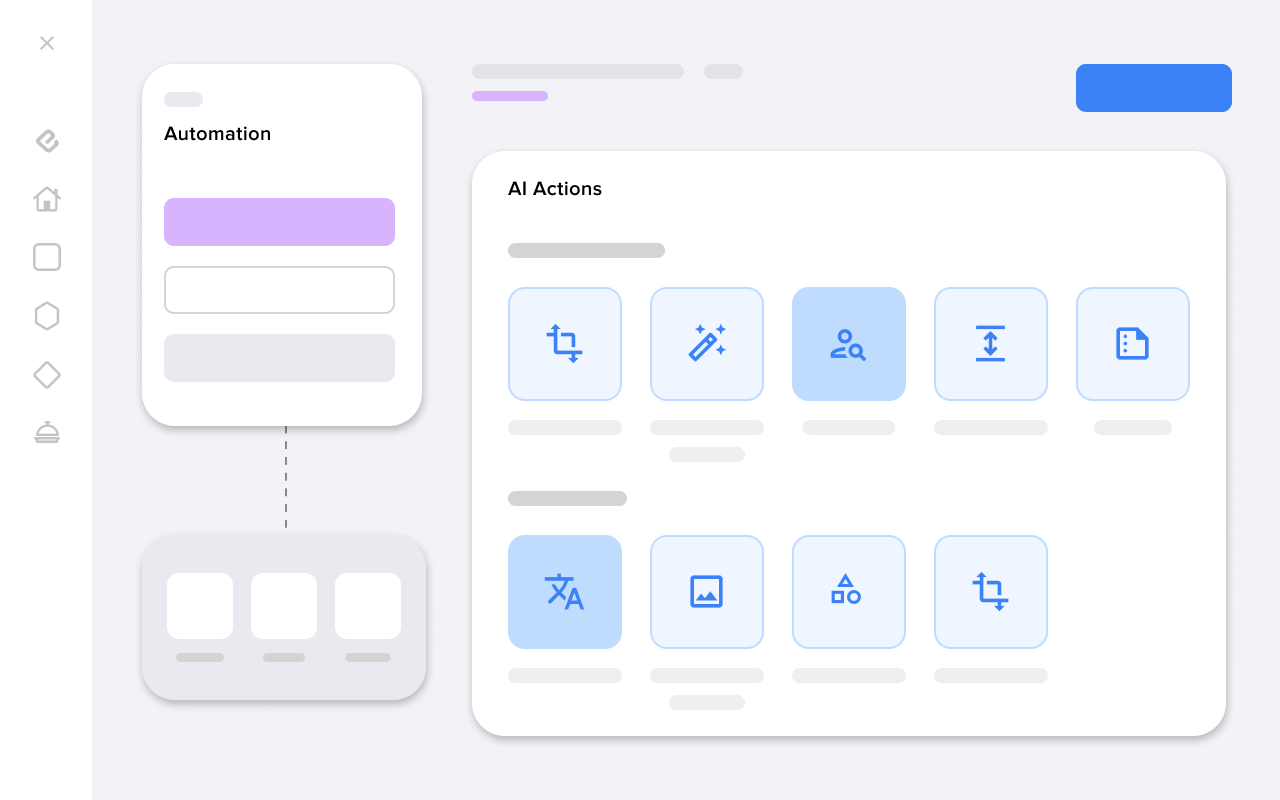

Recreate business processes by prompt or by hand. If you can see it, you can automate it.

Supercharge any process with out-of-the-box AI, ML, and LLMs.

Choose from 100s of pre-built apps, or build your own from scratch. No coding required.

Auto-inherit all security and governance from your data cloud. No data transfers.

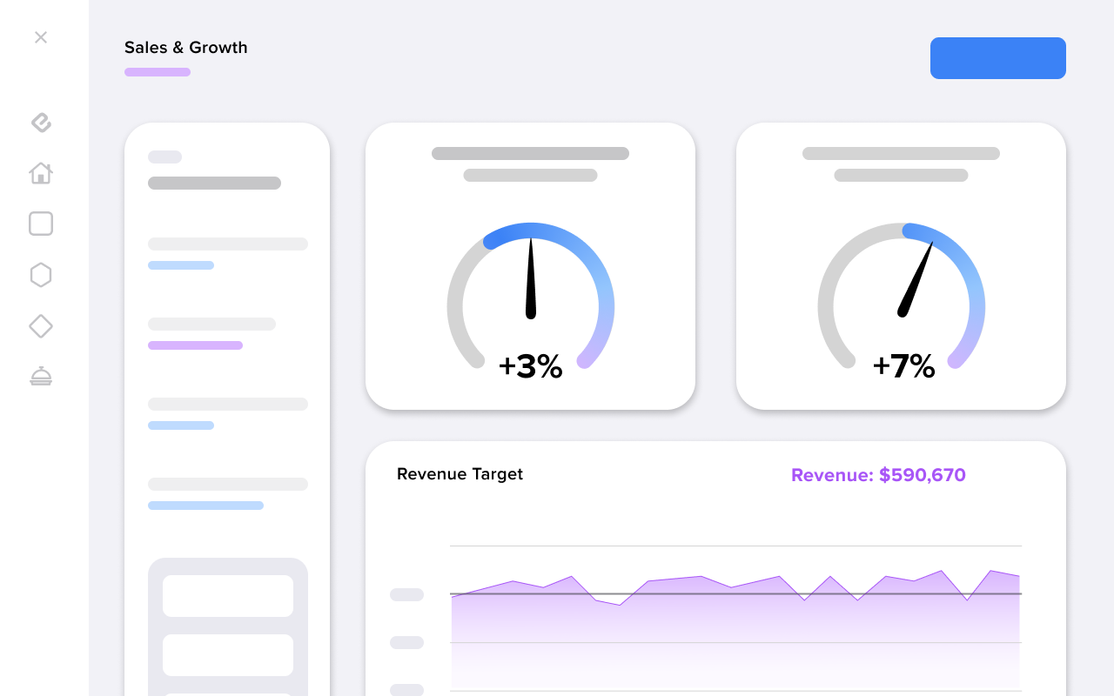

Quantify and track the value of every process automation.

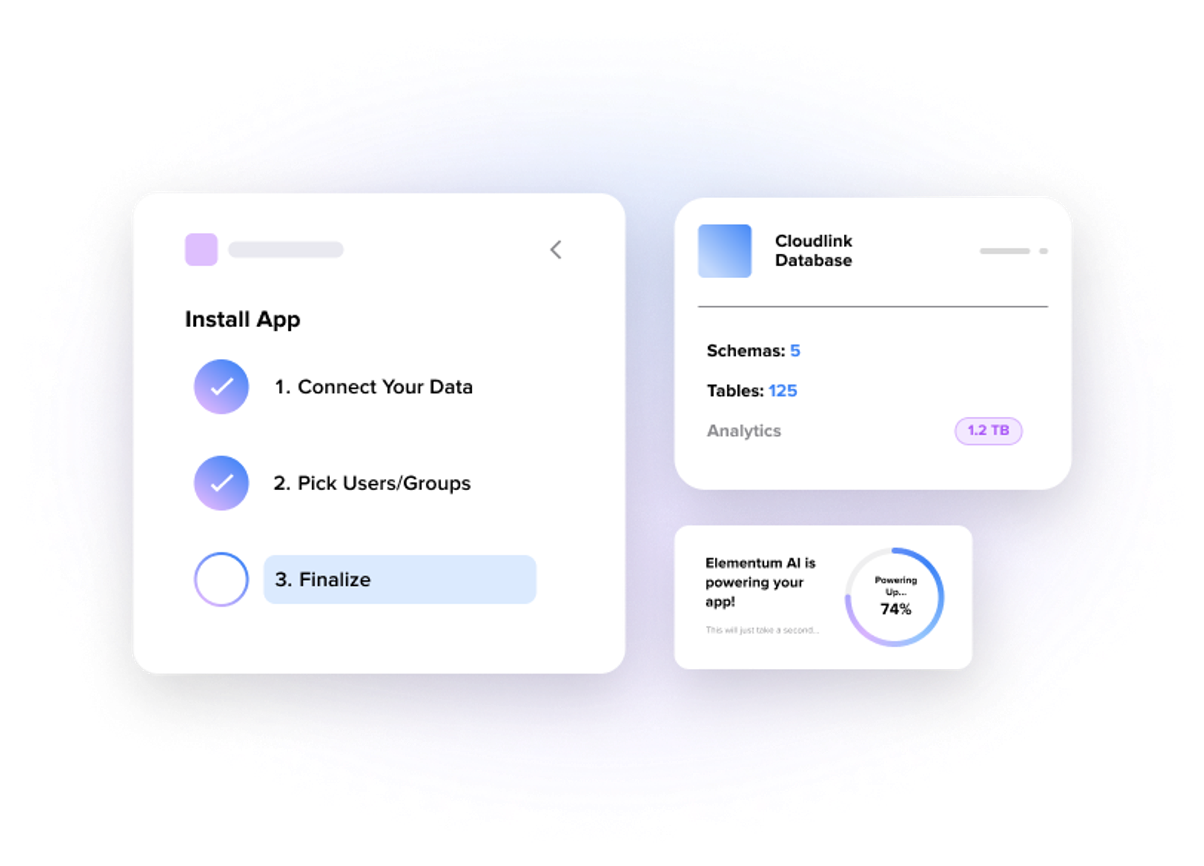

Instantly activate your data with turnkey, AI-powered solutions for every industry.

Go-live in seconds without engineering resources.

Access advanced ML models without in-house expertise.

Track the dollar value of every automation as you go.